180

THROUGHPUT

(lcm/h)

306

Power (KW/HP)

13.0

WEIGHT

(t)

THE COMPACT ONE

The BA 615 shredder is a compact and powerful biomass processor designed primarily for smaller (contract) operations or municipalities. Thanks to its low dead weight of only 11.5 t and a low feeding height of 1.86 m, the BA 615 can be easily transported and fed with small tractors or wheel loaders.

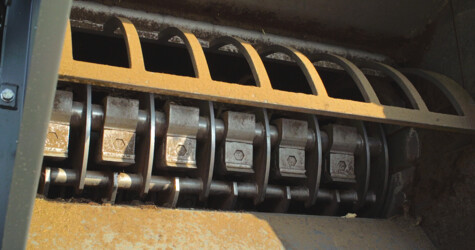

With a 1200 x 615 mm inlet opening and 3800 mm feed length, the JENZ shredder can be used for a wide range of materials such as green waste and bark but also light scrap wood. Due to its rotor speed of over 1,100 rpm, the most compact JENZ shredder is also ideally suited for fine substrate processing.

The BA 615 series

Uniquely good

JENZ biomass processors are the ideal choice for companies that value efficiency, safety and convenience. They achieve uniform material quality, are economical in fuel consumption and reduce the burden on drivers. These shredders are also durable with a high tractive force and offer unique flexibility: One rotor for everything.

DISCOVER ADDITIONAL HIGHLIGHTS

Mode Selecting System

The machine has three preset shredding modes that can be adjusted depending on the source material. For example, green waste can be assigned a separate mode, which is then called up at the push of a button. This saves time and enables even inexperienced operators to make optimum use of the machine.

JES

Standby ModE

The JES (JENZ Energy Saver) mode can shut down the engine to idle at the push of a button if work is interrupted. This stops the conveyor belt and the intake. To continue work, switch back to operation by pressing a button and restart the system.

REMOTE DIAGNOSTICS

To ensure smooth operation of JENZ machines, log data can be transmitted to JENZ on a daily basis. These data help to detect anomalies more quickly and, in the event of an error message, support can be provided quickly and reliably.

Smart HydraulicS

Intelligent hydraulic control allows precise adjustment of the machine to the material and the desired discharge. This ensures high processing quality and maximum efficiency. Diagnostic valves offer easy fault diagnosis - both for the operator and for JENZ Service.

REVERSIBLE FAN

The Cleanfix reversible fan clears the cooler of dust during operation and ensures safe operation, even under difficult dusty conditions.

LED FLOOD LIGHTS

LED flood lights provide high luminosity and illumination, which significantly increase safety when working in the dark.

THE BA 615 – ONE SERIES,

NUMEROUS OPTIONS

BA 615 |  BA 615 Tiger |  BA 615 E | |

Performance | |||

| Garden cuttings (lcm/h) | 140 | 140 | 140 |

| Bark (lcm/h) | 180 | 180 | 180 |

| Scrape wood (lcm/h) | 120 | 120 | 120 |

| Stumps (lcm/h) | not for permanent use | not for permanent use | not for permanent use |

Draw-in | |||

| Draw-in width (mm) | 1200 | 1200 | 1200 |

| Draw-in height (mm) | 615 | 615 | 615 |

| Free loading length (mm) | 3800 | 3800 | 3800 |

| "Silo capacity (m3) " | 4,5 | 4,5 | 4,5 |

Grinding unit | |||

| Number of hammers | 24 | 24 | 24 |

| Rotor diameter | 820 | 820 | 820 |

Conveyor outfeed | |||

| Maximum drop height (mm) | 3700 | 3510 | 2850 |

| Drop height (mm) | 3100 | 2870 | 2850 |

Main drive | |||

| Diesel motor | CAT C7.1 | CAT C7.1 | |

| Power (kW/hp) | 225/306 | 225/306 | |

| AdBlue | Ja | Ja | |

| Emission stage | 5 | 5 | |

| Displacement (l) | 7,01 | 7,01 | |

| Electric motor | 50 Hz, IP 55, IE3, 400V | ||

| Power (kW) | 90 | ||

Chassis | |||

| Top speed (km/h) | 80 | 1 | |

| Chassis version | Central axle trailer | Caterpillar track | |

Weight | |||

| Weight in t * equipment-dependent | 12 | 13 | 11,5 |

| Permitted axle load (t) | 14 | ||

| Permitted support load (t) | 1 | ||

| Permitted total weight (t) | 15 | ||

Transport dimensions | |||

| Dimensions transport position* (LxWxH in m) * equipment-dependent | 9,80 x 2,44 x 3,57 | 8,50 x 2,50 x 3,40 | 8,90 x 2,40 x 3,84 |